Products

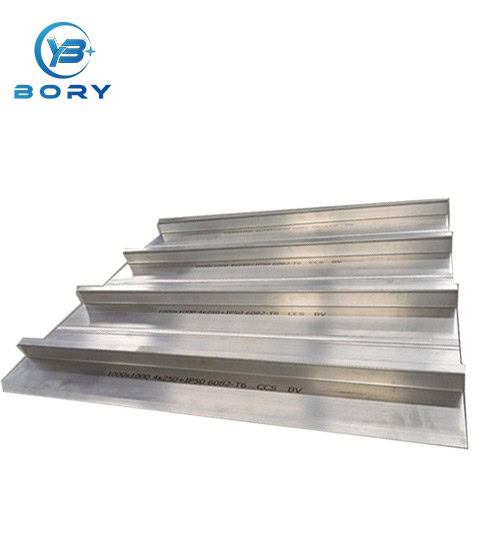

Aluminum Ribbed Plate

Alloy Type: 6082

Width: 500 mm ~ 2400 mm

Thickness: 2 mm ~ 6 mm

Length: 3000 mm ~ 6000 mm

Place of Origin: China

MOQ: 1 ton

Packaging: Export standard packaging

Product Overview

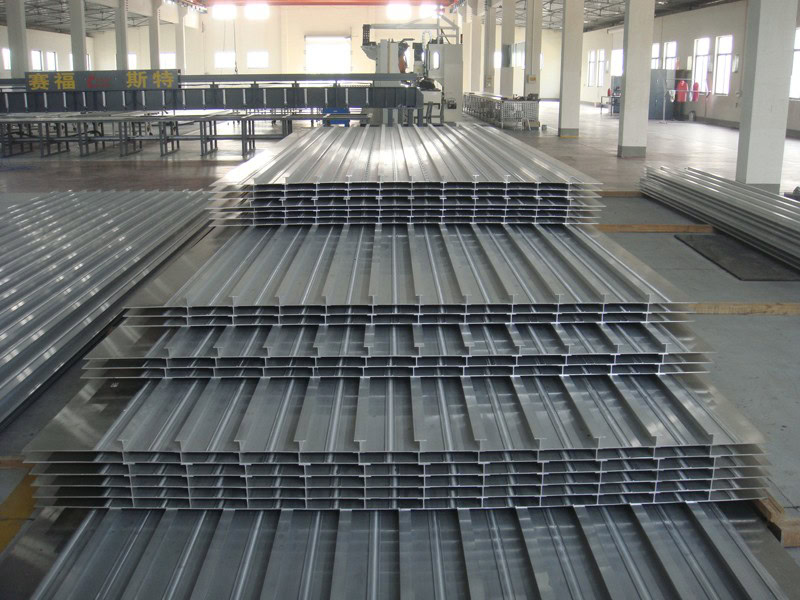

The aluminum ribbed plates are precisely engineered structural materials, specifically designed for use in marine environments. The 6082 aluminum alloy is renowned for its high strength, excellent corrosion resistance, and weldability, providing superior structural support in high-stress areas of the vessel. Compared to traditional steel materials, aluminum ribbed plates significantly reduce the vessel’s weight without compromising strength, helping to improve fuel efficiency and lower maintenance costs.

Product Features

High Strength and Lightweight: The 6082 aluminum alloy offers outstanding mechanical properties, performing exceptionally well under high loads and torque. Its lightweight characteristics greatly reduce the vessel’s weight, thereby improving overall navigation efficiency.

Superior Corrosion Resistance: As a marine-grade aluminum alloy, 6082 exhibits excellent resistance to seawater and salt spray, making it particularly suitable for prolonged exposure to harsh marine environments.

Excellent Weldability: The 6082 aluminum alloy has great weldability, making it easily applicable to the welded structures of ships, streamlining the shipbuilding process for greater efficiency.

Structural Reinforcement Design: The ribbed design with raised longitudinal bars enhances the plate’s bending and torsional strength, making it particularly suitable for heavily loaded areas in the ship’s frame and deck structure.

Applications

1. Ship Structural Reinforcement

Aluminum ribbed plates are widely used in the primary structural parts of ships, especially in keels, ribs, and bulkheads that bear heavy loads. Their high strength and corrosion resistance ensure the long-term stability and safety of the vessel.

2. Decks and Bulkheads

In ship deck and bulkhead structures, aluminum ribbed plates provide essential structural support while maintaining a lightweight profile. They help reduce the overall weight of the vessel, improving both navigation efficiency and stability.

FAQ

Q: Can I request a sample before placing an order?

A: Absolutely. We are happy to provide samples or produce according to your technical drawings or specifications to ensure our products meet your requirements before finalizing the order.

Q: Is it possible to visit your factory?

A: Yes, we warmly welcome clients from around the world to visit our factory. We would be pleased to give you a tour of our facilities and demonstrate our production processes.

Q: How can I receive a quotation for my project?

A: Simply fill out the contact form or send us your project details via email. We strive to respond to all inquiries promptly. You can also reach us through WhatsApp for quick communication.

Q: What information should I provide to get an accurate quotation?

A: To ensure an accurate quote, please provide details such as material type, thickness, width, length, specific requirements, and the total quantity or tonnage you wish to purchase.

Q: Do you perform quality inspections before shipping?

A: Yes, all of our products undergo thorough quality inspections before packaging. We ensure that any defective items are removed from the batch. Additionally, we welcome third-party quality inspections to guarantee compliance with your standards.