Products

Aluminum Plate

Alloy Type: 1050, 1060, 2024, 3003, 5052, 5083, 6061, 6063, 7050, 7075, etc.

Thickness: 1 mm ~ 500 mm

Width: 1000 mm ~ 2400 mm

Length: 500 mm ~ 8000 mm

MOQ: 1 ton

Packaging: Export standard packaging

Product Overview

Bory Metal’s aluminum plates are precision-manufactured to provide high strength, excellent corrosion resistance, and versatility across multiple industries. Known for their exceptional strength-to-weight ratio, our aluminum plates are suitable for both heavy-duty industrial applications and lightweight structural components. Whether for aerospace, marine, or industrial use, our aluminum plates ensure optimal performance in demanding environments.

Common Alloy Types for Aluminum Plates

1. 6061 Aluminum Plate:

One of the most versatile aluminum alloys, combining excellent machinability, strength, and corrosion resistance. Common in construction, aerospace, and general industrial applications.

Applications: Truck frames, shipbuilding, automotive components, and structural parts in construction.

2. 5052 Aluminum Plate

Known for its excellent corrosion resistance, particularly in marine environments. It is highly formable, making it suitable for applications requiring both strength and flexibility.

Applications: Marine structures, fuel tanks, pressure vessels, and appliances.

3. 7075 Aluminum Plate

A high-strength aluminum alloy typically used in aerospace applications where strength is critical. It is heat-treatable and offers excellent stress resistance.

Applications: Aircraft wings, fuselage components, and other aerospace structural parts.

4. 2024 Aluminum Plate

This alloy has high fatigue resistance and is frequently used in aerospace applications due to its excellent strength-to-weight ratio. It is particularly effective in areas requiring good fracture toughness.

Applications: Aircraft structures, truck wheels, and highly stressed parts.

5. 5083 Aluminum Plate

Highly resistant to seawater corrosion, making it ideal for marine and shipbuilding applications. This alloy also offers good weldability and moderate strength.

Applications: Ship hulls, marine structures, and cryogenic equipment.

6. 6063 Aluminum Plate

Typically used for architectural and ornamental applications, 6063 offers excellent surface finish and good corrosion resistance. It’s frequently used in anodized products due to its aesthetic appeal.

Applications: Window frames, door frames, irrigation tubes, and architectural structures.

7. 1060 Aluminum Plate

This is a commercially pure aluminum alloy with excellent corrosion resistance and high thermal and electrical conductivity. It is highly formable and is often used in applications where strength is not the primary concern.

Applications: Electrical conductors, chemical equipment, and food processing equipment.

8. 3003 Aluminum Plate

A popular alloy for general purpose applications, 3003 provides good corrosion resistance and moderate strength. It is highly formable and used in a wide range of applications where workability is essential.

Applications: Roofing, siding, cooking utensils, and storage tanks.

9. 5086 Aluminum Plate

Like 5083, this alloy is also highly resistant to seawater and industrial chemicals. It’s frequently used in applications where high strength and excellent weldability are required.

Applications: Shipbuilding, pressure vessels, and marine equipment.

10. 7050 Aluminum Plate

A high-strength, heat-treatable alloy that provides excellent corrosion resistance, particularly in high-stress environments. It’s a popular choice in aerospace applications where structural integrity is paramount.

Applications: Aircraft landing gear, fuselage frames, and wing skins.

Available Temper Conditions

1. T6 Temper

Available for 6061, 7075, and other alloys, this temper condition offers high strength, making it ideal for structural and heavy-duty applications.

2. T651 Temper

Commonly used with 7075 and 2024 alloys, providing excellent dimensional stability and fatigue resistance for critical aerospace and industrial components.

3. H32 Temper

Primarily for 5052 and 5083 alloys, this temper offers good formability and medium strength, ideal for marine and automotive applications.

4. O Temper (Annealed)

This soft temper is ideal for applications requiring maximum ductility and ease of forming. Suitable for alloys like 1060, 3003, and 5052.

5. H24 Temper

Available for alloys like 1060 and 3003, H24 temper offers medium strength with good formability. It is widely used in applications requiring moderate strength and better resistance to external forces.

6. H116 Temper

Used primarily for marine-grade alloys like 5083 and 5086, H116 temper offers superior corrosion resistance in seawater environments, making it ideal for shipbuilding and marine structures.

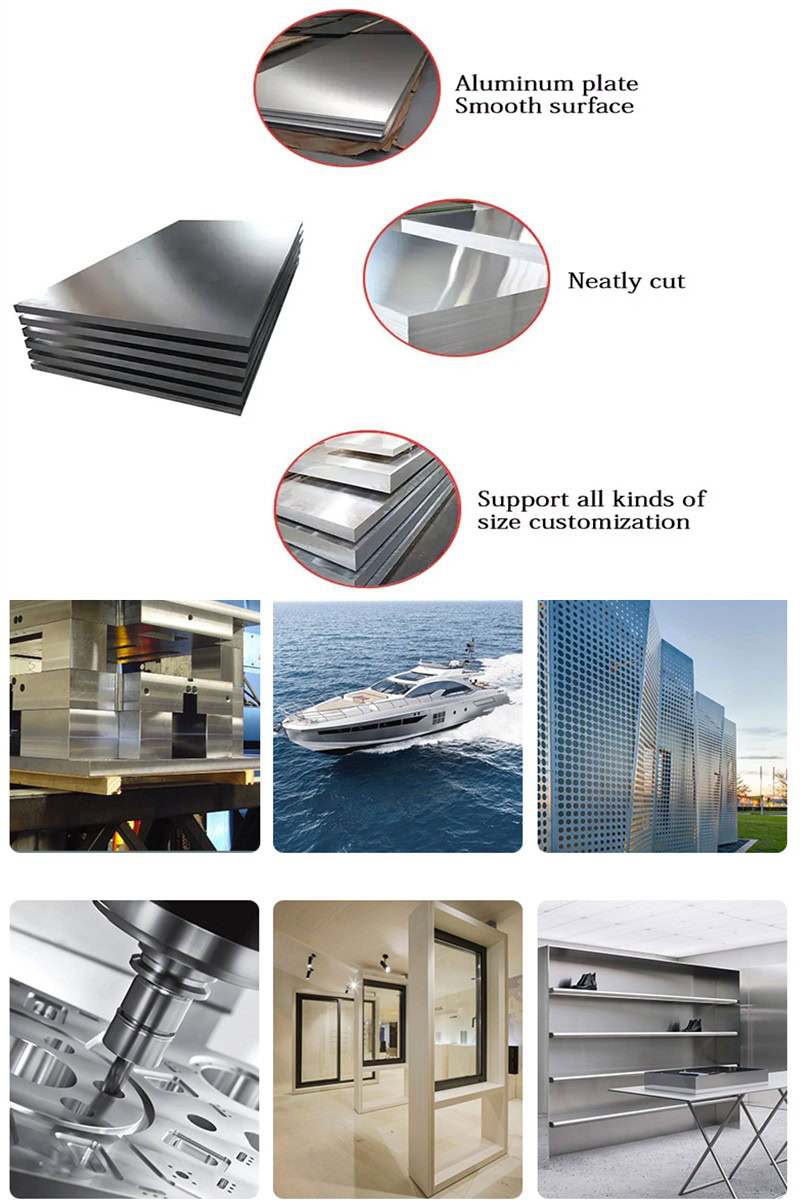

Applications

1. Aerospace

Aluminum plates are essential for lightweight, high-strength components such as aircraft wings, fuselage parts, and landing gear. Alloys like 7075 and 2024 are widely used in the aerospace industry.

2. Marine

Alloys like 5083 and 5086 offer exceptional resistance to seawater, making aluminum plates a preferred material for shipbuilding, marine equipment, and offshore structures.

3. Construction

Aluminum plates provide corrosion resistance and strength for structural applications like roofing, wall panels, bridges, and architectural designs.

4. Automotive

Lightweight yet strong, aluminum plates are used in the automotive industry for body panels, engine components, and heat exchangers.

5. Industrial Manufacturing

Aluminum plates serve in the fabrication of machinery, molds, and industrial tools. Alloys like 6061 and 7050 offer the necessary strength and durability for these demanding environments.

6. Chemical Processing

Alloys such as 1060 and 3003 are highly resistant to chemical corrosion, making them suitable for storage tanks, piping, and heat exchangers in chemical plants.

FAQ

Q: Can I request a sample before placing an order?

A: Absolutely. We are happy to provide samples or produce according to your technical drawings or specifications to ensure our products meet your requirements before finalizing the order.

Q: Is it possible to visit your factory?

A: Yes, we warmly welcome clients from around the world to visit our factory. We would be pleased to give you a tour of our facilities and demonstrate our production processes.

Q: How can I receive a quotation for my project?

A: Simply fill out the contact form or send us your project details via email. We strive to respond to all inquiries promptly. You can also reach us through WhatsApp for quick communication.

Q: What information should I provide to get an accurate quotation?

A: To ensure an accurate quote, please provide details such as material type, thickness, width, length, specific requirements, and the total quantity or tonnage you wish to purchase.

Q: Do you perform quality inspections before shipping?

A: Yes, all of our products undergo thorough quality inspections before packaging. We ensure that any defective items are removed from the batch. Additionally, we welcome third-party quality inspections to guarantee compliance with your standards.