Products

Aluminum Bar

Alloy Type: 2A12, 6061, 6063, 6082, etc.

Length: 2000 mm ~ 6000 mm

Place of Origin: China

MOQ: 1 ton

Packaging: Export standard packaging

Product Overview

Bory Metal’s aluminum bars are precision-manufactured to provide high strength, corrosion resistance, and flexibility across a wide range of industrial and structural applications. Whether you require standard round or square bars, or specialized hexagonal bars, our aluminum products are designed to meet the diverse needs of various sectors, including construction, aerospace, automotive, and manufacturing industries.

Our aluminum bars are available in multiple alloy options, including 2A12, 6061, 6063, 6082, and 7075, offering a wide range of properties to suit specific project requirements. Each alloy is known for its unique combination of strength, machinability, and corrosion resistance, making them suitable for both lightweight and heavy-duty applications.

Common Alloy Types for Aluminum Bars

1. 2A12 Aluminum Bar

A high-strength aluminum alloy commonly used in aerospace applications. Known for its superior machinability and toughness, 2A12 is widely applied in areas where high strength is required.

Applications: Aircraft structures, high-stress parts, and heavy-duty engineering components.

2. 6061 Aluminum Bar

One of the most versatile aluminum alloys, 6061 offers excellent corrosion resistance, high strength, and good weldability. It’s suitable for a wide range of structural applications.

Applications: Structural components, automotive parts, marine fittings, and construction materials.

3. 6063 Aluminum Bar

Known for its excellent surface finish and formability, 6063 aluminum is widely used in architectural and ornamental applications. It also offers good corrosion resistance, making it suitable for outdoor use.

Applications: Window frames, door frames, irrigation systems, and decorative structures.

4. 6082 Aluminum Bar

A heat-treatable alloy with high strength and excellent resistance to stress and corrosion. It’s frequently used in high-load structural applications and the transportation industry.

Applications: Bridges, cranes, scaffolding, and heavy-duty structural components.

5. 7075 Aluminum Bar

A high-strength aluminum alloy typically used in aerospace and other high-stress applications. It offers excellent mechanical properties and resistance to fatigue, making it ideal for heavy-duty parts.

Applications: Aircraft parts, military equipment, and highly stressed structural components.

Available Bar Shapes

1. Round Aluminum Bars

Round aluminum bars are commonly used in industrial and construction applications where strength and precision are critical. They are ideal for machining, structural support, and manufacturing of components.

2. Square Aluminum Bars

Square bars offer higher strength and are often used in structural frameworks and support applications where stability is important. They are commonly found in architectural structures, frames, and outdoor installations.

3. Hexagonal Aluminum Bars

Hexagonal bars are designed for specialized applications where both strength and aesthetic appeal are required. Commonly used in precision machining and parts fabrication, they are ideal for custom components in engineering and construction projects.

Applications

1. Aerospace

Aluminum bars are essential in the aerospace industry for producing lightweight, high-strength components such as aircraft structures, wing parts, and landing gear. Alloys like 2A12 and 7075 are widely used for their exceptional strength-to-weight ratios.

2. Construction

Aluminum bars provide durability and strength for a variety of construction applications, including structural supports, framing, and architectural components. The corrosion resistance of alloys like 6061 and 6063 makes them ideal for both indoor and outdoor use.

3. Automotive

In the automotive industry, aluminum bars are used for manufacturing engine parts, chassis, and other structural components. Their lightweight nature and high strength make them a preferred choice for improving fuel efficiency and performance.

4. Manufacturing

Aluminum bars are extensively used in industrial manufacturing for producing machine components, tools, and equipment. Alloys like 6061 and 6082 are popular for their machinability and strength, providing reliable solutions for precision-engineered parts.

FAQ

Q: Can I request a sample before placing an order?

A: Absolutely. We are happy to provide samples or produce according to your technical drawings or specifications to ensure our products meet your requirements before finalizing the order.

Q: Is it possible to visit your factory?

A: Yes, we warmly welcome clients from around the world to visit our factory. We would be pleased to give you a tour of our facilities and demonstrate our production processes.

Q: How can I receive a quotation for my project?

A: Simply fill out the contact form or send us your project details via email. We strive to respond to all inquiries promptly. You can also reach us through WhatsApp for quick communication.

Q: What information should I provide to get an accurate quotation?

A: To ensure an accurate quote, please provide details such as material type, thickness, width, length, specific requirements, and the total quantity or tonnage you wish to purchase.

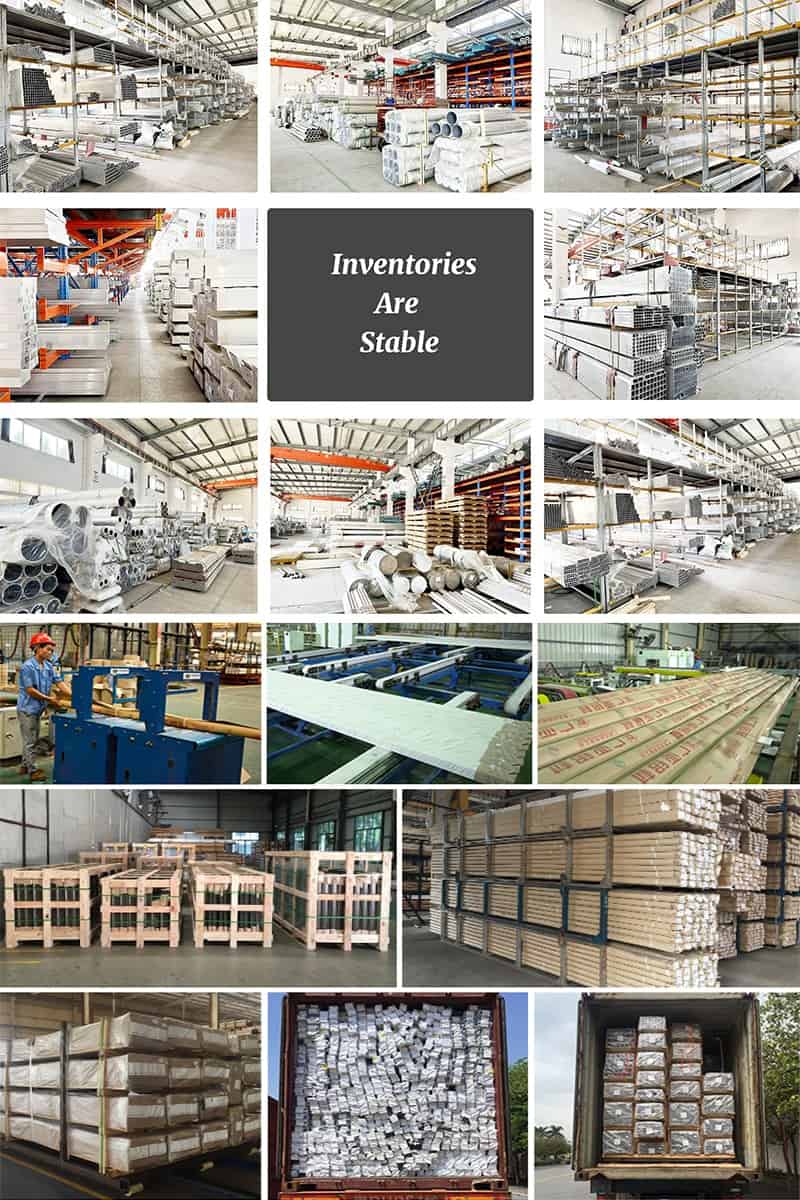

Q: Do you perform quality inspections before shipping?

A: Yes, all of our products undergo thorough quality inspections before packaging. We ensure that any defective items are removed from the batch. Additionally, we welcome third-party quality inspections to guarantee compliance with your standards.